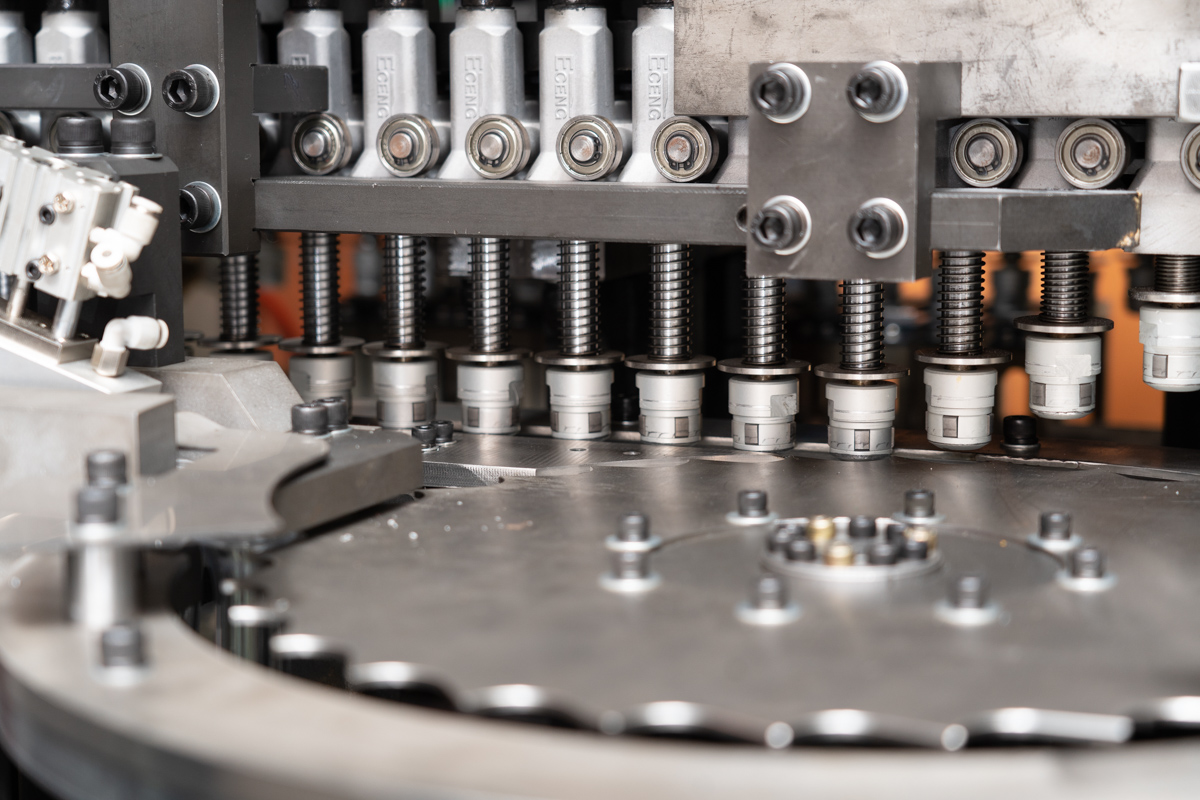

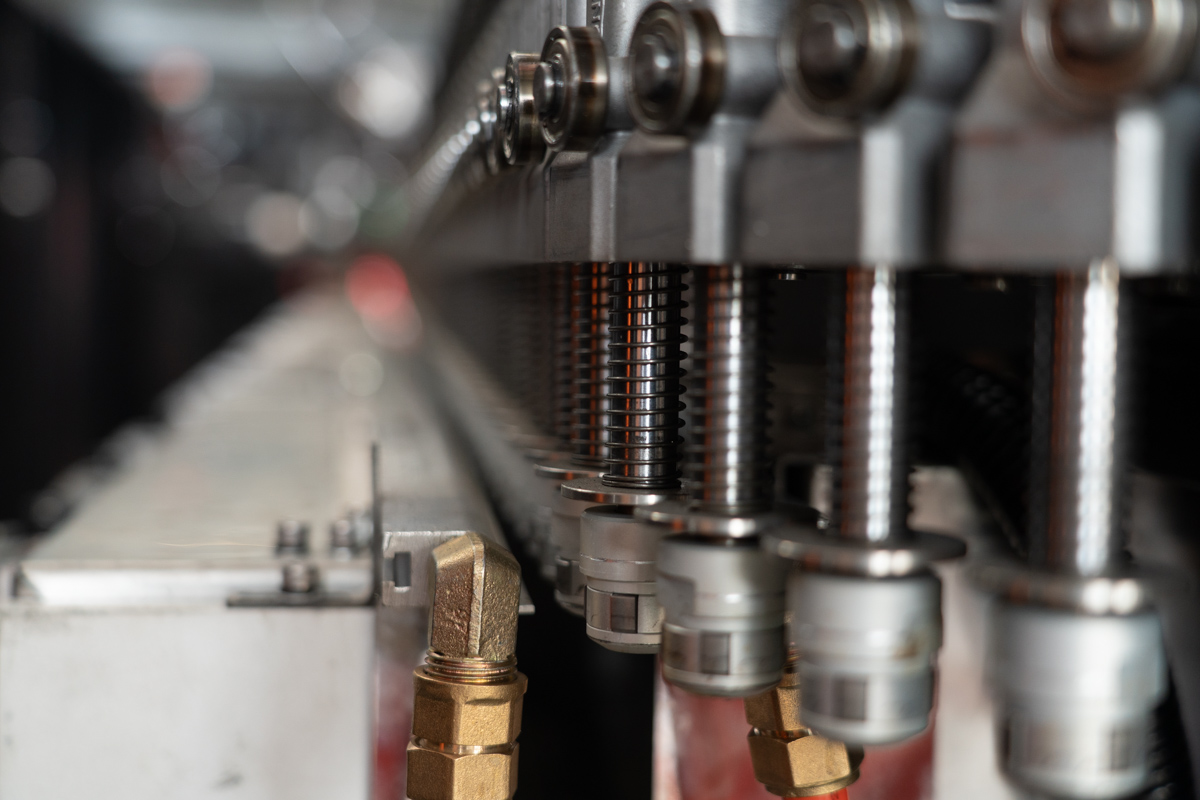

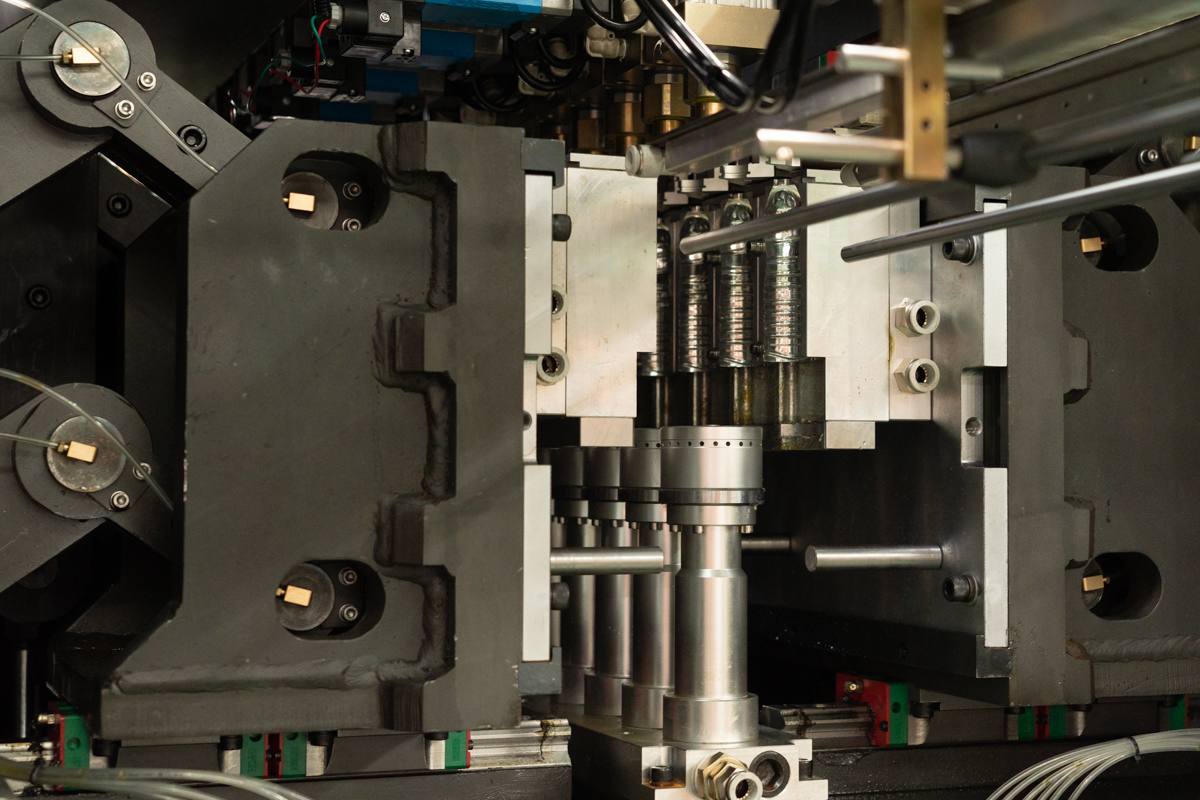

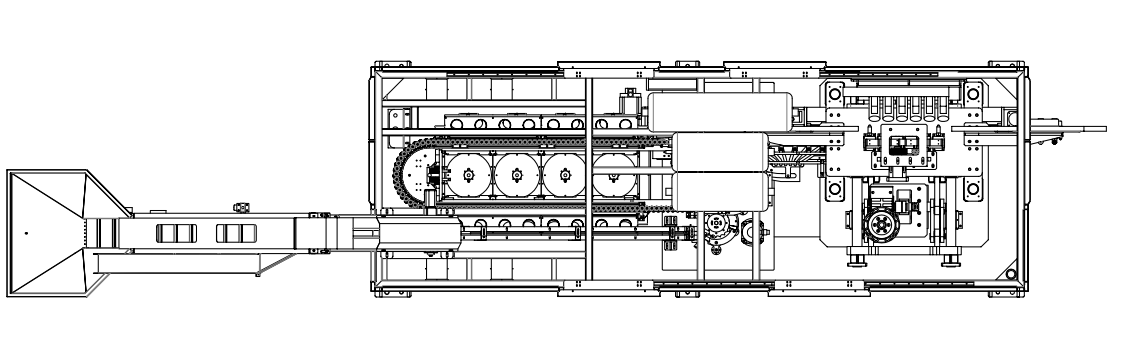

Linear bottle blowing machine is used in the production of PET water bottles,hot filling bottles,carbonated beverage bottles and edible oil bottles.Eceng Machinery K series linear bottle blowing machine stretches the preform by controlling the stretching rod by servo motor. The advantage is that it can be stretched in sections, firstly position the preform,ensure the verticality of the preform when stretching then secondary stretching.Ensure uniformity and consistency of stretch of each preform. At the same time, the blower is faster and less energy consumed.

1. Linear bottle blowing machine, high speed and stability, precise positioning. It adopts advanced microcomputer PLC control system, which runs more stably.

2. The production process is fully automated, with the advantages of low investment, high efficiency, convenient operation, simple maintenance and safety.

3. Servo transmission system, high positioning accuracy, fast speed and good reliability.

4. Suitable for small batch flexible production, wide application range, suitable for customer needs.

5. Improve energy efficiency, save energy and increase production capacity per unit time.

6. The operation mode is manual or fully automatic, and the human-machine interface control is easy to operate.

7. Servo transmission system, high positioning accuracy, fast speed and good reliability.

8. Each mechanical action is equipped with a safety self-locking device. When a certain process fails, the program automatically switches to a safe state.

9. The heat generation and noise are significantly reduced.

10. The bottle scrap rate is less than 0.2%.

| Name | Brand |

| PLC controller | Delta TAIWAN |

| Touch screen | Delta TAIWAN |

| Clamping servo*2 | Delta TAIWAN |

| Stretch servo | Delta TAIWAN |

| Range servo | Delta TAIWAN |

| Bottle out servo | Delta TAIWAN |

| Main chain servo | Delta TAIWAN |

| Cylinder | FESTO Germany |

| Magnet valve | FESTO Germany |

| Photoelectric switch | OMRON Japan |

| Proximity switch | OMRON Japan |

| Contactor | Schneider France |

| Switch power | Schneider France |

| Sensor | Sutonics Korea |

1. Installation and commissioning: We will arrange experienced technicians to carry out commissioning and trial production, and at the same time make the equipment reach the rated production capacity of the production line.

2. Training: Our company provides technical training for customers. The training content includes equipment structure and maintenance, equipment control and operation. After the training, the buyer’s technicians can master the operation and maintenance, can adjust the process and deal with various faults.

3. We can send you a video of the machine running. You are welcome to visit our factory and see the machine running. Third-party testing agencies are also accepted for inspection.

4. We can design the machine according to your requirements, and at the same time we will give you our professional advice, as you know, we have been in this industry for 30+ years.

5. Well-trained and experienced staff will answer all your inquiries in English and Chinese

6. 12-month warranty and lifetime technical support.

7. Provide good after-sales service, if you have any questions, please contact us. Provide after-sales service, if you have any questions, please contact us.

Q: Are you a trading company or a manufacturer?

A: We are a direct-operated factory located in Zhangjiagang City so we can provide you with high-quality machines at a reasonable price, welcome to visit us.

Q: Are all your products produced by yourself or compressed by purchasing other products?

A: We have independent R&D and production teams focusing on manufacturing machines, and we have our own processing center, and all products are manufactured by our technical team.

Q: What is the capacity of your factory?

A: About 100 production lines per year.

Q: How about spare parts?

A: We will send one year’s worth of easily damaged spare parts with the machine and ship them together. During the warranty period, we will provide spare parts at a cost including freight.

Q: How long does it take to install?

A: According to your machine order, we will send one or two engineers to your factory, which takes about 5 days to 25 days.

Q: How to install the machine after it arrives?

A: We will send engineers to your factory to install the machine and train your employees how to operate the machine.

Q: When can I get the machine after payment?

A: Usually the production time is about 30-60 days, depending on the type of machine you ordered. The shipping time is subject to your port of destination.

Q: If we buy your machine, what is your guarantee or warranty on the quality?

A: We provide you with high-quality machines with a 1-year warranty and lifetime technical support.