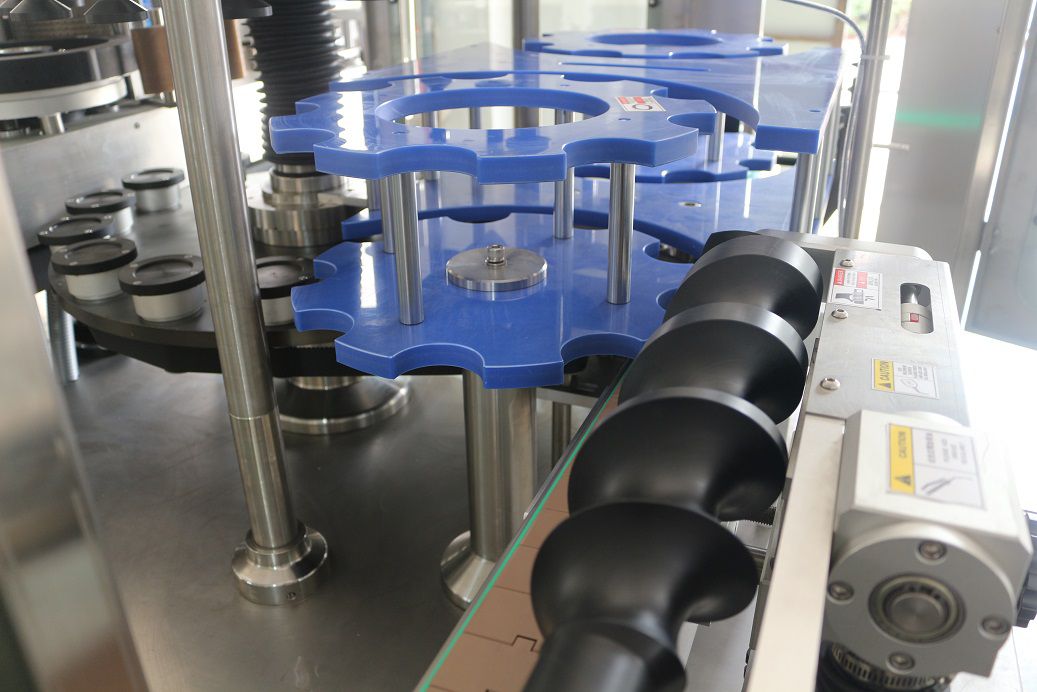

OPP(Hot Melt Glue) labeling machine is rotary and continuous type. It can automatically adjust the driving of bottle inlet and outlet. The bottles driven by the conveyor are separated by the bottle separating screw according to the space of star wheel,then the star wheel transfers the bottles to the turntable.The bottles will be set by the bottle pressing structure and bottle mold base, then the bottles start to self-rotate and label.When the bottles reach the position of electric eye detection,label sending system starts to send labels and then the high speed cutter will cut the label. It adopts high speed servo motor which can ensure the accuracy and stability of label sending and cutting.The cut labels will be sent to the gluing system which will glue two ends of label. This way of gluing can make min consumption of hot glue. The glued labels will be rotated to the labeling position. During label transition,the bottles are in a rotating condition, so the labels can be applied smoothly and tightly to the bottles.The glued ends of label can be overlapped well. Thus, the labeling process finished.

1. Automatically cut and label the bottle in a round or semi-circular shape. Automatically melt the glue to label the upper and lower parts, and automatically recycle the glue.

2. Variable speed control system, synchronous automatic detection system, automatic adjustment of production speed, always keep the labeling machine at the best production speed

3. Star wheel separation feeding, high-speed labeling with associated design transmission method, stable accuracy.

4. Servo motor synchronous tracking, combined with specially designed vacuum roller adsorption, accurate and stable labeling

5. In case of abnormal situation, the machine is equipped with a safety device and automatically stops immediately.

6. The machine has the function of automatic shutdown and alarm.

7. The whole machine has a centralized lubrication system for easy cleaning, lubrication and maintenance.

8. Electronic automatic deviation correction and guidance system, ultrasonic digital electronic eye, non-contact electric eye, automatic adjustment of label position. (optional).

9. The upper and lower difference of the label is within 2mm.

| No. | Item | Parameter data |

| 1 | Power supply | Three-phase 380V 50 Hz 8000W |

| 2 | The total length of equipment | 3000mm (conveyor length 3000mm or can be regulate base on your product lines) |

| 3 | Equipment width | 2500mm |

| 4 | Conveyor speed | 30m/min (the speed of the transmission lines can be adjusted according to actual production) |

| 5 | The method of speed adjustment | uninterrupted – adjust rate |

| 6 | The largest Speed of labels feed | maximum speed of 100 meters labels / min |

| 7 | The largest speed of labeling | 12000 PCS/H |

| 8 | Labeling accuracy | ± 1mm |

| 9 | Integrated Labeling accuracy | ± 1mm |

| 10 | Product Size | 500ml |

| 11 | Maximum label width | 150mm |

| 12 | The maximum length of label | 500mm |

| 13 | The maximum diameter of label | 600mm |

| 14 | Paper core diameter | 152 mm |

| 15 | Labeling glue | leading and trailing edge gluing with hot melt |

| 16 | Gluing temperature | 120~160℃ |

| 17 | Type of label | opp label 、paper-plastic composite film label、paper label |

| 18 | Labeling workstation | 12 per cycle |

| 19 | The quantity of labeling mold | one suit (to be satisfied with one product, each mold contains infeed worm 、infeed starwheel 、discharge starwheel、 position bottle and so on ) |

| 20 | Machine weight | about 3000 Kg |

1. Installation and commissioning: We will arrange experienced technicians to carry out commissioning and trial production, and at the same time make the equipment reach the rated production capacity of the production line.

2. Training: Our company provides technical training for customers. The training content includes equipment structure and maintenance, equipment control and operation. After the training, the buyer’s technicians can master the operation and maintenance, can adjust the process and deal with various faults.

3. We can send you a video of the machine running. You are welcome to visit our factory and see the machine running. Third-party testing agencies are also accepted for inspection.

4. We can design the machine according to your requirements, and at the same time we will give you our professional advice, as you know, we have been in this industry for 30+ years.

5. Well-trained and experienced staff will answer all your inquiries in English and Chinese

6. 12-month warranty and lifetime technical support.

7. Provide good after-sales service, if you have any questions, please contact us. Provide after-sales service, if you have any questions, please contact us.

Q: Are you a trading company or a manufacturer?

A: We are a direct-operated factory located in Zhangjiagang City so we can provide you with high-quality machines at a reasonable price, welcome to visit us.

Q: Are all your products produced by yourself or compressed by purchasing other products?

A: We have independent R&D and production teams focusing on manufacturing machines, and we have our own processing center, and all products are manufactured by our technical team.

Q: What is the capacity of your factory?

A: About 100 production lines per year.

Q: How about spare parts?

A: We will send one year’s worth of easily damaged spare parts with the machine and ship them together. During the warranty period, we will provide spare parts at a cost including freight.

Q: How long does it take to install?

A: According to your machine order, we will send one or two engineers to your factory, which takes about 5 days to 25 days.

Q: How to install the machine after it arrives?

A: We will send engineers to your factory to install the machine and train your employees how to operate the machine.

Q: When can I get the machine after payment?

A: Usually the production time is about 30-60 days, depending on the type of machine you ordered. The shipping time is subject to your port of destination.

Q: If we buy your machine, what is your guarantee or warranty on the quality?

A: We provide you with high-quality machines with a 1-year warranty and lifetime technical support.